Aramid Fibres

There are two different molecular structures of aramids (aromatic polyamides), the meta- and the para structure.

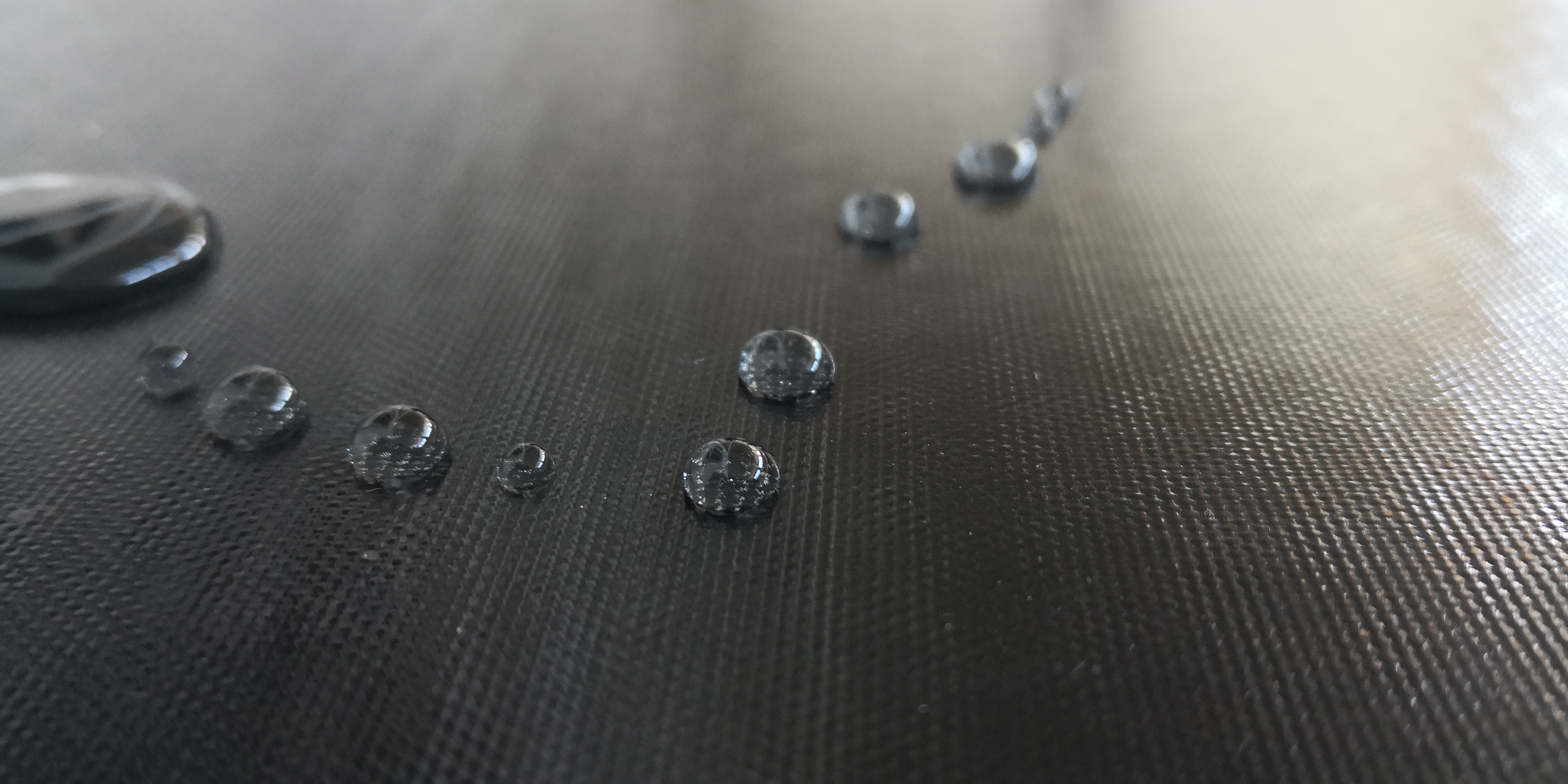

Aramids are hardly flammable, but the flame goes out as soon as the fire source is removed. The fibres do not melt and provide good flame-retardant properties. At high temperatures the fibres start to carbonize. After several days at a continuous temperature of 250 °C, the residual tensile strength is still 50% of the initial strength. Aramid shows a small thermal expansion and a low heat transfer coefficient. Aramids are resistant to bacteria, mould as well as most solvents, lubricants and salt water. However, aramids are degraded by strong acids and alkalis.

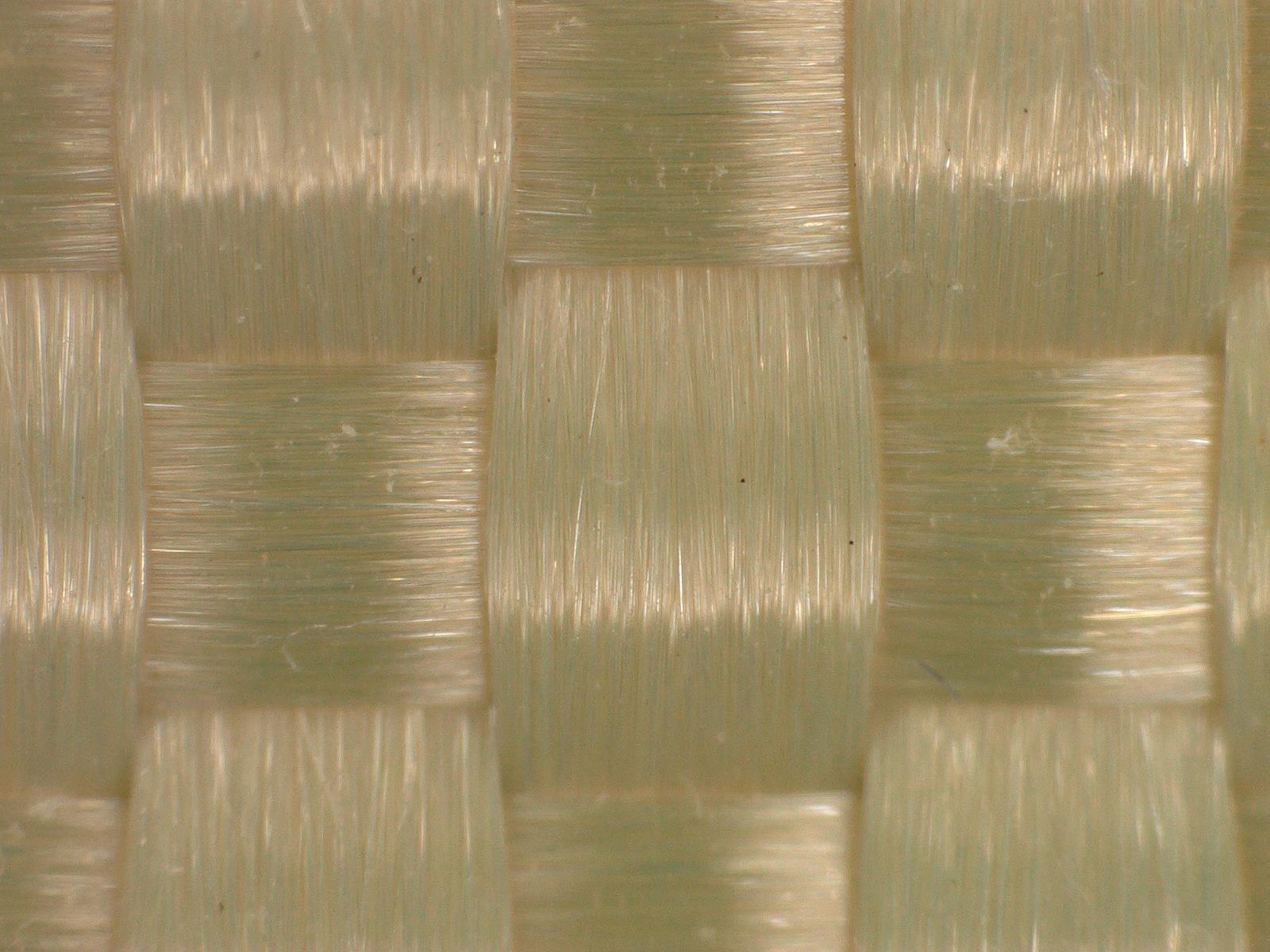

Para-aramid displays a high tensile strength, temperature resistance and resistance to alternating bending. Thus para-aramid is used in ballistic applications and as reinforcement in plastics. Para- aramid with a PTFE or silicone coating is used as material for conveyor belts, edge reinforcements and as sheets for compactors.

Due to its textile character, meta-aramid is used as a staple fibre in flame-retardant textiles. Meta- aramid fabrics are used as edge reinforcements and reinforcements for conveyor belts. Fabrics based on meta-aramid are not suitable for PTFE or silicone coating due to their filamentation and the resulting rough surface. In addition, the high strain is not acceptable.

Contact Person

Philipp Kümmerle

Customer Support & Technology

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Matthias Grübel

Development

This email address is being protected from spambots. You need JavaScript enabled to view it.